The exponential growth of AI and High-Performance Computing (HPC) is placing unprecedented demands on data center infrastructure, particularly the physical layer. As fiber counts soar, efficient installation, deployment, and ongoing management of high-density fiber optic cable assemblies become paramount. As an OEM/ODM, we understand these challenges intimately and continuously refine our approaches. This article explores key best practices and innovative approaches to optimize your data center’s fiber backbone, drawing insights from industry leaders.

Strategic Installation and Cable Management: Building a Resilient Foundation

Effective cable management is the bedrock of a high-performance, future-ready data center. It’s not just about aesthetics; it directly impacts network reliability, performance, and operational efficiency.

- Pre-terminated Solutions for Speed and Reliability:The consensus among industry leaders like CommScope and Siemon is a strong lean towards factory-terminated, pre-assembled fiber optic trunk cables. These “plug-and-play” systems offer significant advantages over field termination, including:

- Reduced Installation Time:Factory-controlled processes are inherently faster, leading to quicker deployment.

- Superior Performance:Precision termination in controlled environments minimizes insertion loss and ensures consistent, high-quality connections.

- Lower Overall Cost:While the initial cable cost might be slightly higher, the savings in labor, reduced rework, and faster commissioning often lead to a lower total cost of ownership.

- Enhanced Reliability:Factory testing of each assembly guarantees performance from day one, reducing troubleshooting.

- Space Optimization in High-Density Environments:Data centers are constantly striving for higher density within existing footprints. Innovations like ultra-high-density enclosures and the adoption of Very Small Form Factor (VSFF) connectors (e.g., MMC, SN) allow for more fiber terminations in less rack space. Careful planning of cable routing paths and the use of smaller diameter fiber (e.g., 200-micron) contribute significantly to optimizing valuable real estate.

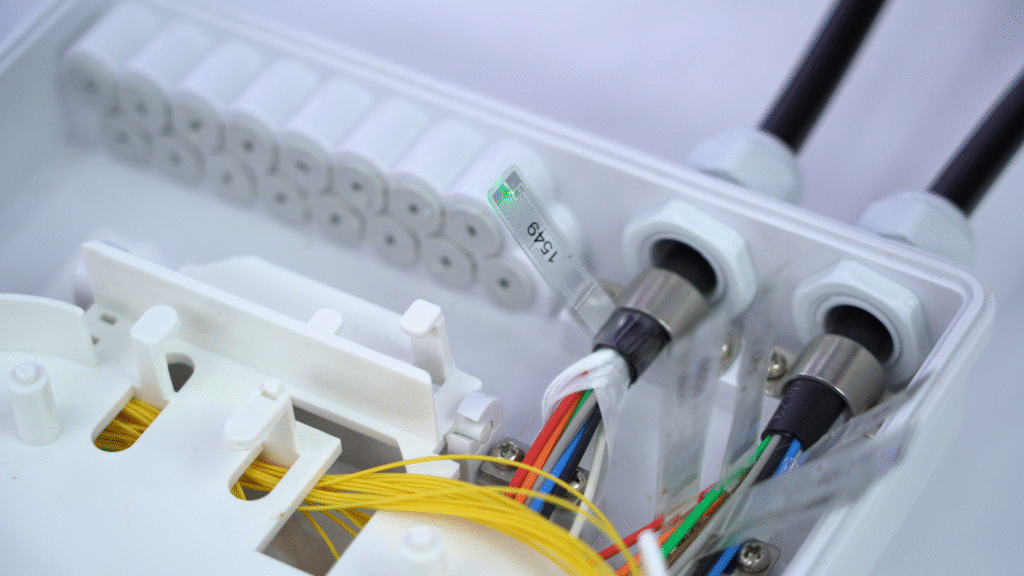

- Maintaining Optical Performance through Proper Handling:Fiber optic cables are delicate. Adhering to strict guidelines for minimum bend radius and maximum pulling tension during installation is critical to prevent signal loss and physical damage. Solutions like CommScope’s FiberGuide® raceway systems help maintain the correct bend radius throughout the system, ensuring long-term reliability.

Next-Generation Labeling: Precision and Intelligence in a Dense World

In a high-density fiber environment, clear, comprehensive, and accessible labeling transforms troubleshooting and simplifies moves, adds, and changes (MACs). Traditional labeling methods, while foundational, are being augmented by more intelligent solutions.

- Classic Basic Labeling:Industry-standard color codes (like TIA/EIA-598 for fiber and jacket types) and basic alphanumeric labels at both ends of a cable remain essential for quick visual identification. Labels should be durable, legible, and permanently affixed.

- Enhanced Labeling with QR Codes:Moving beyond basic identification, QR codes offer a significant leap forward. By scanning a QR code on a fiber cable, technicians can instantly access a wealth of stored digital information, which can include:

- Detailed product specifications and datasheets.

- Comprehensive test reports and calibration certificates.

- Maintenance history and installation dates.

- Crucially, this can be extended to include specific routing information, such as the cable’s precise origin, destination points, and intermediate pathways within the data center. This level of detail vastly reduces time spent on identification and verification during maintenance or upgrades.

- RFID for Ultimate Traceability and Automation:Radio-Frequency Identification (RFID) tags represent the pinnacle of next-generation labeling for fiber management. Unlike barcodes or QR codes, RFID tags do not require a direct line of sight, allowing for faster, simultaneous reading of multiple cables, even in dense bundles.

- Key Advantages:

- Non-Line-of-Sight Reading:Enables rapid inventory checks and identification without needing to physically see or manipulate each cable.

- Greater Data Storage:RFID tags can store more comprehensive data, including maintenance logs, usage history, and real-time status updates, directly on the chip.

- Real-time Tracking & Automation:Integrated with management software, RFID systems allow for real-time tracking of cable location, status, and lifecycle, preventing human error and significantly improving efficiency in cable management. Some RFID tags even feature LEDs that flash when activated, guiding technicians directly to the cable in question.

- Durability and Environmental Adaptability:RFID tags are often more robust and can withstand harsh data center environments, making them ideal for long-term asset management.

- The Supplier’s Role in Intelligent Labeling:For effective next-generation labeling, your OEM/ODM partner must possess the tools, resources, and technical acumen to implement these diverse solutions. They need to deeply understand your specific design and the installer’s mindset to provide truly understandable, clear, and customized labels, whether classic, QR code-enhanced, or RFID-integrated.

Optimized Packaging and Sequencing: Streamlining Deployment

Efficient deployment extends beyond the cable itself to how it’s packaged and delivered. For high-density projects, where multiple cables might have the same length but distinct origins, destinations, and routing paths, intelligent packaging and sequencing are critical.

- The “Same Length, Different Path” Dilemma:This common scenario in large data center builds can lead to significant installation errors and delays if cables are not properly differentiated.

- Supplier Solutions for Intelligent Packaging and Sequencing:An ideal OEM/ODM partner goes beyond standard bulk packaging. They leverage their excellent capacity and prioritization abilities to sequence production as requested, offering solutions such as:

- Customized Kitting and Bundling:Tailored kitting solutions where all necessary cables for a specific rack or installation zone are bundled together. This significantly reduces on-site sorting time and ensures installers have the right components readily available.

- Route-Specific Labeling on Packaging:The outer packaging itself should clearly indicate the intended rack, row, or even specific routing path for the cables within. This facilitates quick staging and minimizes misplacement.

- Optimized Drum/Reel Sizes and Cable Winding:While not “sequencing” in the routing sense, suppliers can optimize cable winding onto smaller drums or reels, especially for high-fiber count cables. This eases transportation, storage, and handling in confined data center spaces.

- Phased and Just-In-Time Delivery:Working with suppliers for phased or just-in-time deliveries ensures that only the cables needed for an immediate installation phase are on-site, reducing clutter, potential damage, and the risk of using the wrong cable.

- Reduced On-Site Complexity:When cables arrive factory-terminated, quality-assured, intelligently labeled, and precisely sequenced (to the extent possible through the supplier’s production and logistical prowess), it transforms the installation process from a complex construction project into a highly efficient assembly, significantly reducing labor costs and accelerating time-to-market for critical AI/HPC deployments.

The Path Forward

As data centers continue their relentless pursuit of higher bandwidth and greater density, the emphasis on robust physical layer infrastructure will only grow. Embracing pre-terminated solutions, implementing intelligent digital labeling systems (including QR codes and RFID), and leveraging optimized and sequenced cable delivery will be critical for achieving the scalability, efficiency, and reliability required for next-generation AI and HPC environments.

Call to Action: We’re constantly striving to meet the evolving needs of the high-density fiber market. What are your biggest struggles when it comes to deploying and managing high-density fiber in your data center? Do the solutions proposed here resonate with your challenges, or do you have other innovative approaches you’re exploring? Share your insights and experiences with us – your perspective is invaluable!

Sources: