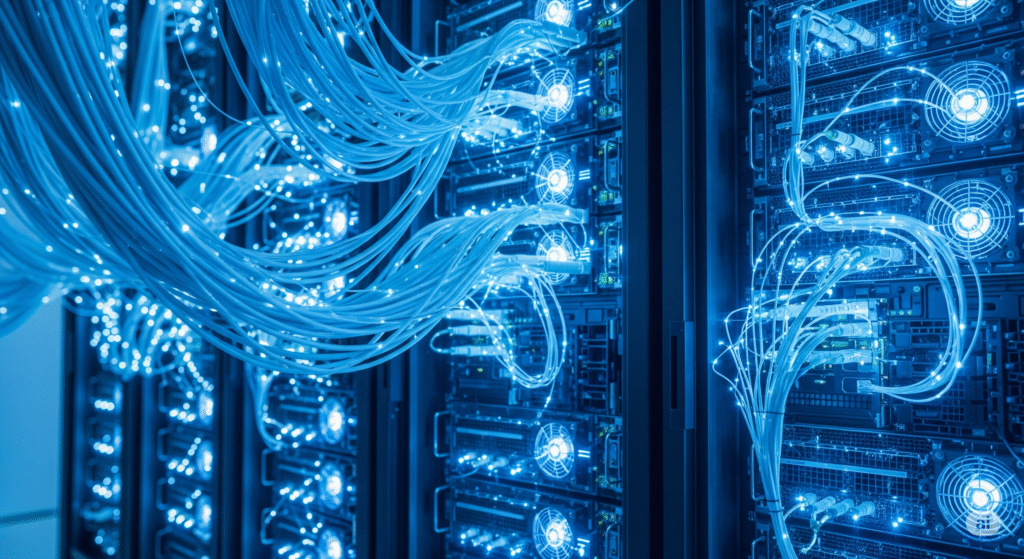

The digital landscape is being reshaped by the insatiable demands of Artificial Intelligence (AI), cloud computing, and High-Performance Computing (HPC). These transformative technologies require an unprecedented level of high-density fiber connectivity, pushing the boundaries of network infrastructure. As an OEM/ODM fiber cable assembly and connectivity manufacturer, we see firsthand the immense growth in demand for these critical components. Looking ahead, it’s becoming increasingly clear that the ability to secure a robust and scalable supply chain will be a decisive factor for success.

The Unprecedented Demand for Fiber

AI architectures, with their intensive back-end, front-end, and in-band management requirements, are driving an exponential increase in fiber optic connections. Training and inference processes generate vast amounts of data, necessitating high-speed, low-latency links that only fiber can reliably provide. We are rapidly moving towards 800G and even 1.6T Ethernet, with AI workloads demanding many times more fiber than traditional data center setups. This surge in demand directly translates to an escalating need for high-fiber-count cables—from 288 to 864 fibers and beyond—and massive quantities of 8F and 16F patch cords within racks.

The Challenges of Scaling Production

While the demand is clear, meeting it presents significant challenges for manufacturers:

Which aspects should drive your supply chain choice?

Industry forecasts suggest that in the mid-future, the demand for these specialized fiber optic solutions will likely outstrip the available production capacity. This potential supply crunch underscores a critical consideration for any enterprise building out its AI, cloud, or HPC infrastructure: choosing the right supplier or distributor that has the right manufacturing partner.

As an OEM/ODM, our role extends beyond simply supplying products; it’s about being a strategic extension of your supply chain. When selecting a partner for your fiber cable assembly and connectivity needs, consider these crucial factors:

In a rapidly accelerating market where connectivity is the backbone of innovation, securing a reliable and capable manufacturing partner is paramount. Ensure your chosen partner can not only meet your current needs but also scale to support your ambitious future. Their capacity and commitment to high-yield production will be a critical asset in navigating the high-stakes world of AI, cloud, and HPC infrastructure.

If you want to know more about us, you can fill out the form to contact us and we will answer your questions at any time.

We use cookies to improve your experience on our site. By using our site, you consent to cookies.

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

These cookies are needed for adding comments on this website.

These cookies are used for managing login functionality on this website.

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Google Analytics is a powerful tool that tracks and analyzes website traffic for informed marketing decisions.

Service URL: policies.google.com (opens in a new window)

Clarity is a web analytics service that tracks and reports website traffic.

Service URL: clarity.microsoft.com (opens in a new window)

You can find more information in our Cookie Policy and Privacy Policy for ADTEK.

2 Responses

whoah this blog is excellent i really like studying your posts.

Keep up the great work! You already know, a lot of persons are looking round for this information, you can help them greatly.

I like the valuable info you provide in your articles. I will bookmark your weblog and check once more right here frequently.

I am slightly sure I’ll be told a lot of new stuff proper right here!

Good luck for the next!