As fiber networks extend deeper into access, mobile fronthaul, and outdoor data infrastructure, connectivity reliability under real-world conditions has become a defining challenge. Dust contamination, frequent mating cycles, limited installation environments, and long-term maintenance constraints are reshaping how connectors are designed and deployed.

Expanded Beam Optics (EBO) has re-emerged as a highly practical optical interconnect approach for these scenarios. With growing deployment in FTTx, 5G/6G transport, and outdoor data aggregation points, EBO technology is gaining renewed attention as networks demand both performance stability and operational simplicity.

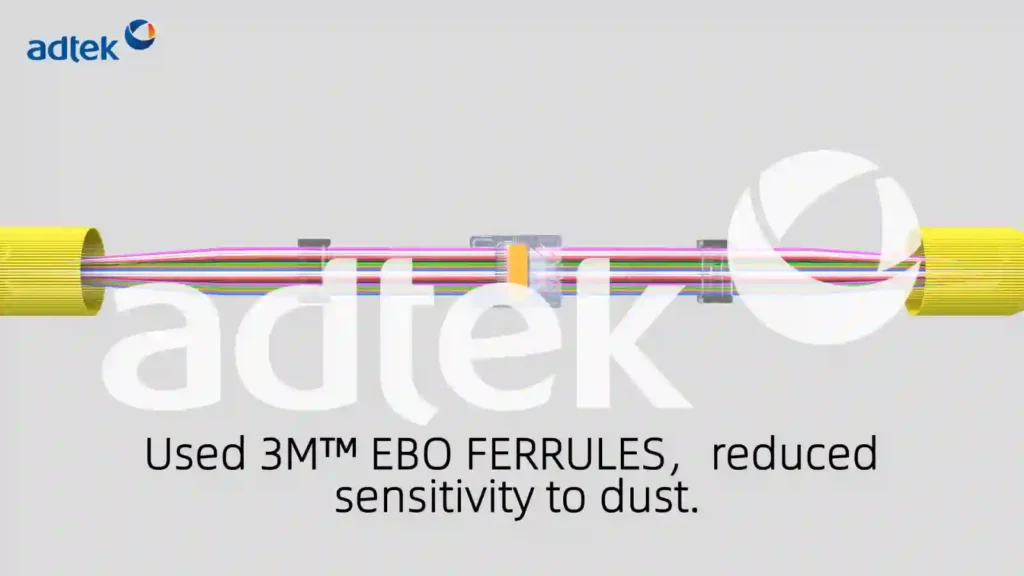

Expanded Beam Optics is an optical coupling method that enlarges the light beam before transmission and refocuses it at the receiving interface. Unlike traditional physical-contact fiber connectors, EBO systems rely on collimated beam expansion and focusing, significantly relaxing alignment tolerances.

According to Marcuse theory, once the beam diameter is expanded, lateral alignment sensitivity is greatly reduced. This directly translates into:

Lower insertion loss sensitivity to transverse misalignment

Significantly reduced vulnerability to dust and surface contamination

Stable optical performance across repeated mate/de-mate cycles

These characteristics make EBO especially suitable for environments where clean-room conditions cannot be guaranteed.

Several market trends are accelerating the adoption of EBO-based connectivity:

Outdoor Fiber Expansion

FTTx, 5G fronthaul, and edge aggregation nodes are increasingly deployed in roadside cabinets, poles, and base stations. These environments expose connectors to dust, moisture, vibration, and temperature variation.

Operational Efficiency Pressure

Network operators seek faster installation, reduced cleaning procedures, and fewer field failures. Connector designs that minimize dependency on specialized tools and cleaning materials directly reduce OPEX.

High-Fiber-Count Interfaces

As fiber counts increase in access and aggregation layers, connectors must deliver both robustness and manageable installation workflows without sacrificing density.

In this context, EBO offers a balanced solution between optical performance and real-world deployability.

Based on 3M™ EBO ferrule technology, the ADTEK EBO QC68 Connector is designed as a fast-install, outdoor-grade optical interface optimized for harsh environments.

From an engineering perspective, the QC68 connector focuses on structural versatility and manufacturing efficiency:

A unified design supporting both single-mode and multimode fibers

Compatibility across 12-fiber and 16-fiber configurations

Interchangeable internal structures enabling adaptation to EBO, MPO, or LC interfaces within a common housing platform

This modular approach simplifies inventory management and supports flexible network architectures without redesigning the entire connector ecosystem.

From the installer’s viewpoint, the QC68 connector addresses some of the most common field challenges:

Low dust sensitivity significantly reduces cleaning requirements and minimizes performance degradation caused by contamination

Tool-free quick-lock mechanism, combining push-pull insertion with a 60-degree rotation, enables fast and secure installation

Bidirectional rotational locking prevents incorrect mating orientation while providing clear tactile and audible feedback

IP68-rated sealing ensures long-term water resistance for outdoor deployment

These features are particularly valuable in scenarios where splicing or maintenance must be performed remotely, such as in service vehicles or temporary field setups.

Modern optical networks rely on interoperability across multiple subsystems. The ADTEK EBO QC68 Connector is designed to mate with established EBO-based interfaces, including MPO EBO platforms used in high-density outdoor and transport applications.

This interoperability allows network designers to integrate EBO connectivity into existing architectures without introducing proprietary lock-in, supporting long-term scalability and system flexibility.

Beyond connector design, large-scale deployment depends on manufacturing maturity. ADTEK’s in-house production capabilities enable:

Consistent optical and mechanical quality across high-volume production

Flexible customization for different fiber counts, interface formats, and application requirements

Rapid transition from engineering validation to mass deployment

This combination of engineering depth and manufacturing scalability ensures that EBO-based solutions can move efficiently from concept to real-world networks.

As fiber networks continue to move closer to the edge—into outdoor cabinets, mobile infrastructure, and distributed access points—the importance of dust-tolerant, easy-to-install, and mechanically robust connectivity will only grow.

Expanded Beam Optics is no longer a niche solution. It is becoming a foundational technology for next-generation outdoor optical networks, where performance stability and operational efficiency must coexist.

If you want to know more about us, you can fill out the form to contact us and we will answer your questions at any time.

We use cookies to improve your experience on our site. By using our site, you consent to cookies.

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

These cookies are needed for adding comments on this website.

These cookies are used for managing login functionality on this website.

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Google Analytics is a powerful tool that tracks and analyzes website traffic for informed marketing decisions.

Service URL: policies.google.com (opens in a new window)

Clarity is a web analytics service that tracks and reports website traffic.

Service URL: clarity.microsoft.com (opens in a new window)

You can find more information in our Cookie Policy and Privacy Policy for ADTEK.

One Response

Hello! I just would like to give a huge thumbs up for the great info you have here on this post. I will be coming back to your blog for more soon.