Installing last-mile fiber often feels like an obstacle course. Crews race against weather and permits – pulling cables through muddy streets, cramped basements, or downspouts in pouring rain. Every step is painstaking: digging new ducts or unlocking hardened enclosures; measuring and splicing each fragile strand by hand. Traditional methods are slow and labor-intensive. For example, one field report found that adding even a single fusion splice could turn a cabinet install from 6–9 hours into 2-5 hours. Across the industry, operators list the biggest headaches: site access delays, extreme environments, limited space, meager crews, and finicky connectors. Key pain points include:

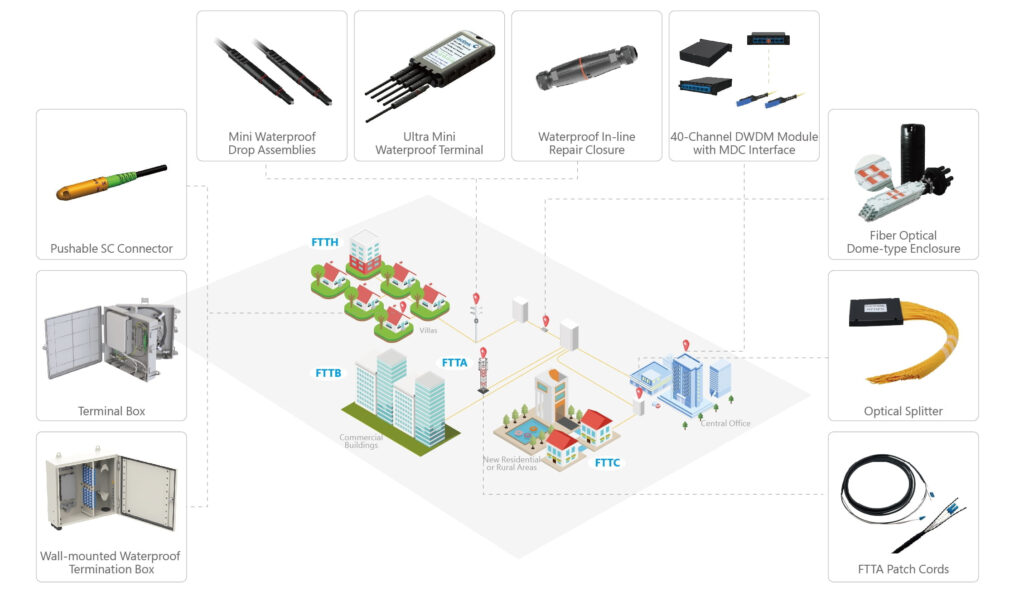

Each of these challenges – from safety and speed to reliability – demands a field-ready fix. ADTEK’s engineers have taken this feedback to heart. Rather than off-the-shelf components, ADTEK’s portfolio delivers plug-and-play, hardened solutions crafted for real sites. Below are the innovations addressing these pain points head-on:

The BDFB is a rugged in-line coupler for “blind” installations. It’s an IP68-rated, weatherproof junction that technicians can pull fiber into without needing direct access or sight. In practice, a crew can push the pre-terminated fiber ends into each side of the bridge – even through a hidden wall cavity or conduit – and hear a solid click as they lock. This means no excavation or extra handholes to splice; the sensitive mating happens inside the sealed BDFB enclosure. By moving the connection point into a factory-like controlled module, BDFB slashes on-site work and exposure. Field tests of similar pre-terminated links confirm dramatic time savings: plug-and-play cables often install in only ~20% of the time of fusion-spliced drops. In short, the BDFB turns a complex, weather-exposed splice into a quick indoor task – solving both site access and deployment-speed headaches at once.

When space is at a premium, ADTEK’s UMHA Terminal Box with its matching Ultra-Mini Hardened simplex connector shines. The terminal box is a tiny, fully sealed drop termination (about the size of a small alarm box), rated for outdoor use. Inside sits ADTEK’s new Super-Mini connector – a breakthrough push-click SC-style coupler whose front end is up to four times smaller than legacy hardened connectors. It still delivers IP68-level protection and an impressive 450 N pull strength, but in a fraction of the volume. For the installer, this means: mount the box on a balcony rail or cramped wall, then with one hand strip the drop fiber and push it into the connector until it snaps into place. No threading, no tools, no epoxying. The result is a fully factory-polished, weatherproof SC/APC drop point that passes first-time coupling nearly 100% of the time. In many MDUs or business-ready installations, this “miniaturized” design replaces bulky enclosures and extra splice trays. It dramatically cuts turn-up time (installers report finishing UMHA drops in minutes instead of hours) and eliminates one more SKU from inventory.

ADTEK’s SC Pushable Connector is a field-fit, glue-less SC/APC drop connector engineered for speed. It’s built around a slim (~7 mm) rubberized boot that can be pushed through very narrow conduits. In the field, a technician simply strips the 900 µm fiber, inserts it into the pushable SC until a built-in spring latch grabs the strand, and seals it off. Because the connector ferrule is pre-polished in the factory, there is no curing or polishing step in the field – just plug, pull, and go. This translates to huge time savings: actual deployments show that using pushable connectors can reduce drop-install time to only a few minutes (roughly 20% of the usual spliced-install time). Moreover, by using standard SC/APC geometry, the connector mates with conventional adapters, avoiding the compatibility headaches of proprietary plugs. Overall, the SC Pushable Connector tackles both speed and simplicity: even crews with minimal fusion-splicing skill can achieve factory-grade connections in seconds, all while fitting into tighter ducts and loops.

For the most brutal conditions, ADTEK offers the Harsh Environment Connector (HEC) – an industry-leading waterproof fiber interface. Based on US Conec’s new HEC DC design, this is an SC/APC connector built for the field. It sports an IP68-rated, rubberized housing only 19 mm in diameter, enabling very dense packing on wall plates and terminals. Its magic is the DirectConec push-pull boot: technicians can simply push the connector into the adapter until it audibly clicks , with no screw threads to line up. Even better, the HEC’s patented blind-mate ferrule guide means you don’t have to see the port – installers can mate connectors by feel or with thick gloves on. As one Conec engineering note explains, “no risk of contaminating the ferrule as you feed the connector into the adapter”. In practice, this eliminates the number-one failure mode (dirty endfaces) and lets crews connect in rain or darkness without error. The HEC thus ensures that outdoors or in dusty manholes, fiber links stay stable and clean – solving environmental ruggedness and reliability challenges.

Each ADTEK solution above is a direct response to field feedback. By moving critical work into the factory or into smarter hardware, these products shrink deployment time, reduce on-site errors, and protect against the elements. They embody “engineering for the field” – rugged, plug-and-play, and purpose-built to make the last mile as smooth as possible. As one Japanese proverb reminds us:

“Fall seven times, stand up eight.” – Japanese Proverb

If you want to know more about us, you can fill out the form to contact us and we will answer your questions at any time.

We use cookies to improve your experience on our site. By using our site, you consent to cookies.

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

These cookies are needed for adding comments on this website.

These cookies are used for managing login functionality on this website.

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Google Analytics is a powerful tool that tracks and analyzes website traffic for informed marketing decisions.

Service URL: policies.google.com (opens in a new window)

Clarity is a web analytics service that tracks and reports website traffic.

Service URL: clarity.microsoft.com (opens in a new window)

You can find more information in our Cookie Policy and Privacy Policy for ADTEK.