A new year, a new journey! 丨New Year’s Message from the Chairman

A new year, a new journey! 丨New Year’s Message from the Chairman On the last day of 2022, away from home, I cruised through

Shenzhen ADTEK Technology Co., Ltd., established in 2007, is committed to technology, quality, and service, actively expanding and striving for excellence, and has established itself as a leader in China’s optical communication industry. ADTEK has implemented a practical quality management system, strictly following ISO 9001:2015 standards for quality management and ISO 14001:2015 standards for environmental management. They rigorously control quality, continuously improve product design, production, and service quality, and respond to the increasing product quality requirements of their customers, ensuring the delivery of high-quality products to their clients.

In order to meet the growing market demands and provide customers with high-quality products, ADTEK recently integrated and updated its reliability laboratory located in Dacao, Shenzhen. This marks the first public disclosure of information about the reliability laboratory, so let’s explore the newly revitalized ADTEK reliability laboratory together:

The all-new reliability laboratory is divided into three areas based on the equipment’s functions: the environmental testing area, the mechanical testing area, and the material testing area. Each area’s equipment plays a specific role, collectively ensuring the smooth operation of the reliability laboratory. The precision, stability, and reliability of these devices are crucial support for ADTEK’s production work. Next, we will introduce the key equipment in each area:

200-channel environmental testing system.

Function:

Insertion loss and return loss testing.

Main Purpose:

It can simultaneously test 200 samples, monitoring the attenuation and reflectivity of products at 1310nm, 1490nm, 1550nm, and 1625nm, along with their change graphs.

Single (multi) mode 48-channel insertion and return loss tester.

Function:

Testing insertion loss and return loss of single (multi) mode products.

Main Purpose:

It can simultaneously test 48 samples, monitoring the attenuation and reflectivity of products at 1310nm, 1490nm, 1550nm, and 1625nm, along with their change graphs.

Equipment Name:

RoHS 2.0 spectrometer.

Function:

Detection of phthalates (BBP, DIBP, DBP, DEHP).

Main Purpose:

For the detection of phthalate content in plastic materials.

Equipment Name:

X-ray Fluorescence Spectrometer.

Function:

Detection of RoHS 6 hazardous substances.

Main Purpose:

Testing for RoHS directive compliance, including halogen content, heavy metal content, alloy testing, and plastic component testing.

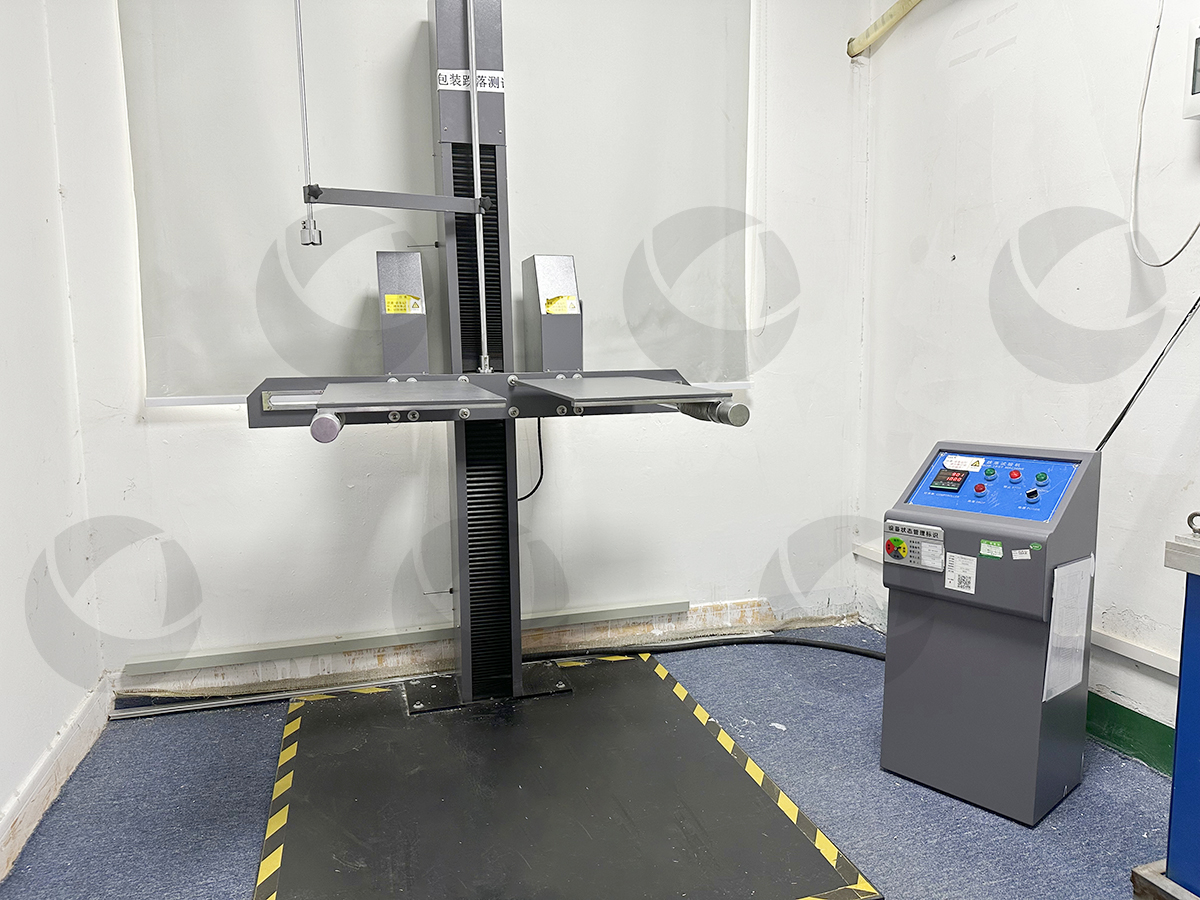

Equipment Name:

Packaging Drop Test Machine.

Function:

Testing for drop-related issues.

Main Purpose:

Used for product packaging design and carton quality testing.

ADTEK’s Dakan reliability laboratory not only boasts a multitude of high-end equipment but is also backed by a professional team.

Their expertise and extensive experience are key to the efficient and stable operation of the reliability laboratory equipment. ADTEK will continue to expand and enhance the laboratory, making the equipment more advanced and the personnel more professional, to continue providing customers with reliable and stable products.

2023.11.1

A new year, a new journey! 丨New Year’s Message from the Chairman On the last day of 2022, away from home, I cruised through

ADTEK’s Housewarming Celebration and Joint Lab Unveiling Ceremony was held grandly! On Saturday, December 18, 2021, Shenzhen ADTEK Technology Co., Ltd. held a grand Housewarming

ADTEK‘s First Skill Competition丨Fighting personal style and charm of production line ADTEK‘s First Skill Competition In order to enhance the quality consciousness and operational skills

2022 OFC丨ADTEK new products debut! Meet you at San Diego Convention Center The Optical Fiber Communication Expo and Symposium (OFC) is the highest specification, largest,

If you want to know more about us, you can fill out the form to contact us and we will answer your questions at any time.

We use cookies to improve your experience on our site. By using our site, you consent to cookies.

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

These cookies are needed for adding comments on this website.

These cookies are used for managing login functionality on this website.

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Google Analytics is a powerful tool that tracks and analyzes website traffic for informed marketing decisions.

Service URL: policies.google.com (opens in a new window)

Clarity is a web analytics service that tracks and reports website traffic.

Service URL: clarity.microsoft.com (opens in a new window)

You can find more information in our Cookie Policy and Privacy Policy for ADTEK.