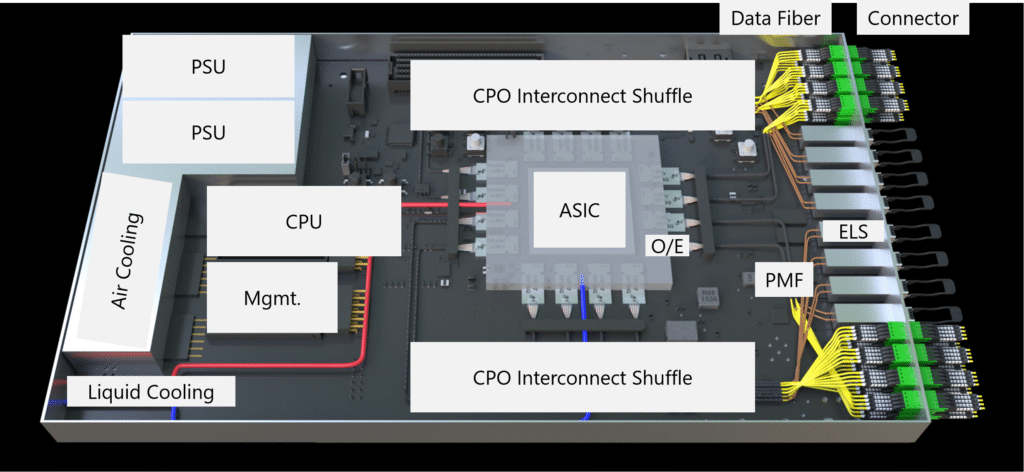

With the rapid development and growth of AI, cloud, and high-performance computing, the demand for computing and switching capacity in data centers is growing exponentially. This has led to several technical constraints and challenges, such as increases in power consumption, bandwidth, latency, and reliability. One of the upcoming solutions to fulfill these requirements is Co-Packaged Optics (CPO), where the Optical Engine (O/E) is positioned close to the switch chip (ASIC). This reduces the length of the electrical circuits on the printed circuit board (PCB), which in turn reduces power consumption, latency, and signaling crosstalk. This close integration also allows channels to reach 100 Gb, 200 Gb, and potentially 400 Gb speeds at very high densities. According to Yole, the global CPO market will reach $2.6 billion by 2033, and the explosion of AI computing power is accelerating the mass production penetration of this technology.

Because the O/E is so closely integrated with the ASIC, the optical signal needs to be routed to the front-plate of the switch, which presents its own challenges. First, we’re dealing with a high density of fibers, up to 1024 fibers per ASIC for data traffic. Then, there’s the restricted space within the switch, where fibers must share space with the PSU, cooling systems (such as ventilators and, if applicable, liquid cooling), the data plane (ASIC), O/E, control plane (CPU), management interface, and connectors. Finally, there’s the need for connectivity over Polarization-Maintaining Fiber (PMF) for the External Laser Source (ELS). These have been separated from the O/E to provide better stability and serviceability. This means all these cables need to be neatly dressed and tightly routed (i.e., with a small bending radius) within the confined space of the switch.

Why the Need for a CPO Interconnect Shuffle?

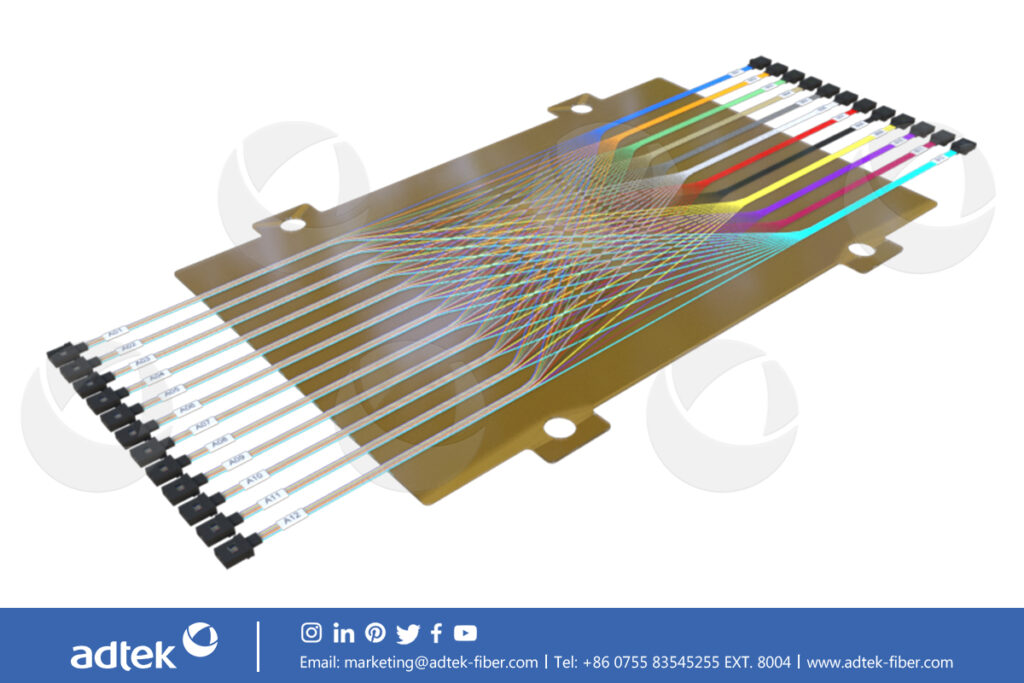

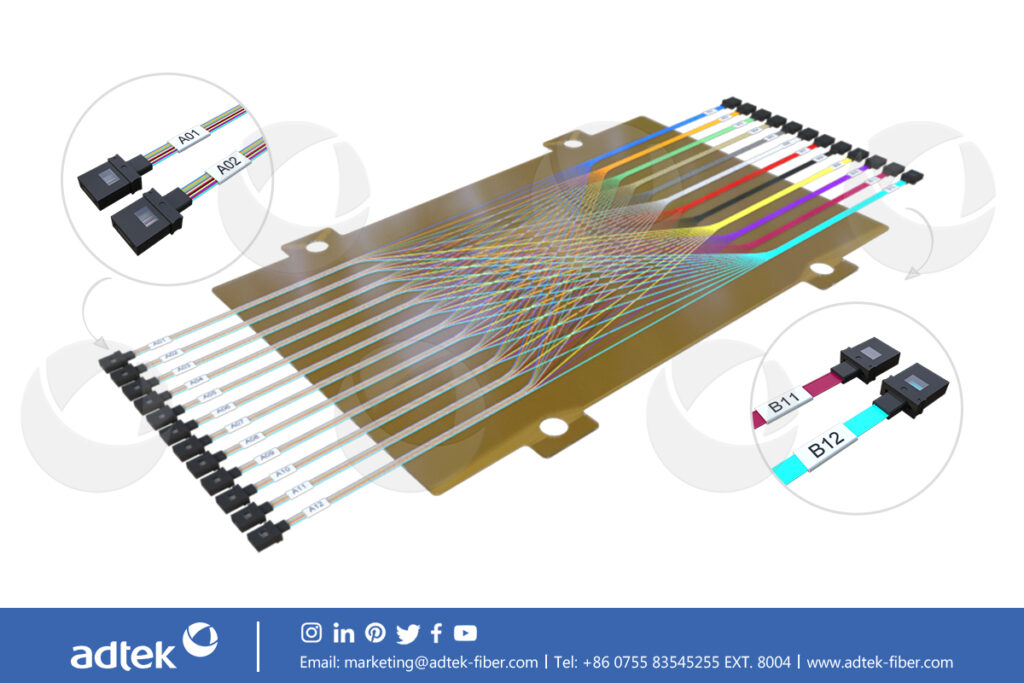

The grouping of fiber channels on the O/E differs from standard MPO or LCD connectors and needs to be re-organized between leaving the O/E and reaching the front-plate connectors. We also have a mixture of connectivity, where data signals leave the O/E, but the ELS PMF feeds the O/E with stable laser light. By ensuring the cables are segregated per engine allows each O/E to be separately serviceable, thus improving the reliability of the switch. The Shuffle can route 200 µm, 250 µm, 600 µm, or 900 µm fibers with a precision of <0.1 mm in complex patterns and bends, in a reliable and repeatable way, to ensure every connection delivers maximum performance.

What are the Main Features of the CPO Interconnect Shuffle?

ADTEK’s Shuffle Solution

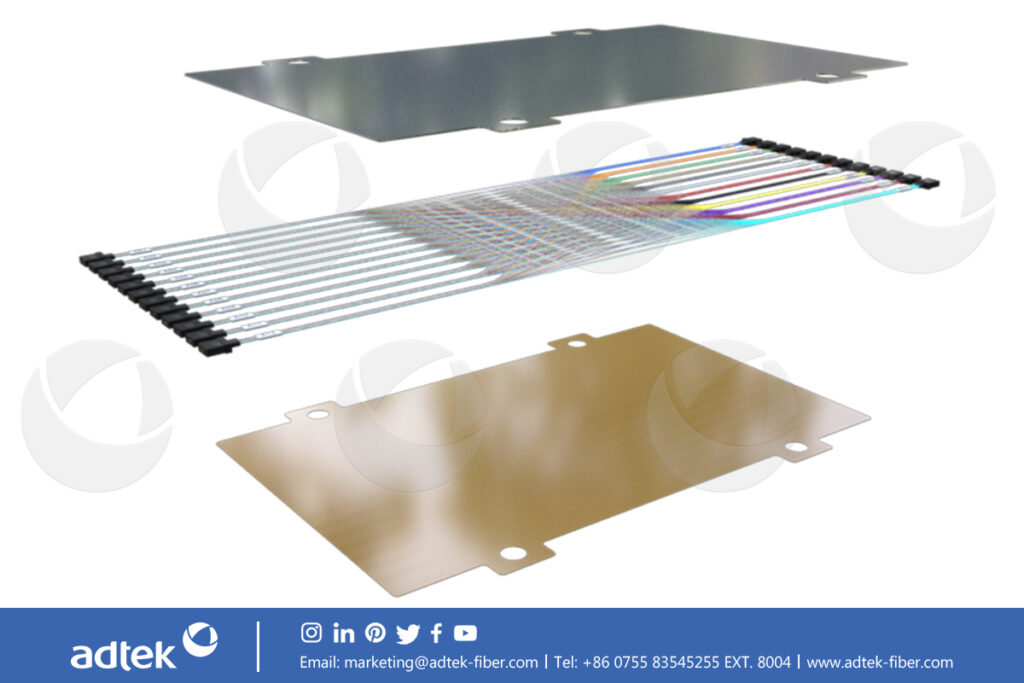

As a leading provider of optical connectivity solutions, ADTEK closely follows market trends and officially launches its high-density optical fiber management solution based on polyimide flexible board. The ADTEK CPO Interconnect Shuffle is an innovative solution for confined spaces with integrated connectivity on flame-retardant substrates.

With the continuous explosion of AI computing power and the acceleration of data center high-density processes, the transmission rate of Serdes has increased, and the iteration of CPO technology is accelerating. The popularization of CPO technology is not only an inevitable choice for the computing revolution but will also reshape the optical interconnection architecture of data centers. ADTEK will continue to deepen its expertise in CPO optical fiber interconnection, with the Shuffle flexible optical circuit board as its core, to provide global customers with highly adaptable and reliable solutions and help build a more efficient, more reliable, and greener next-generation optical interconnection network.

If you want to know more about us, you can fill out the form to contact us and we will answer your questions at any time.

We use cookies to improve your experience on our site. By using our site, you consent to cookies.

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

These cookies are needed for adding comments on this website.

These cookies are used for managing login functionality on this website.

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Google Analytics is a powerful tool that tracks and analyzes website traffic for informed marketing decisions.

Service URL: policies.google.com (opens in a new window)

Clarity is a web analytics service that tracks and reports website traffic.

Service URL: clarity.microsoft.com (opens in a new window)

You can find more information in our Cookie Policy and Privacy Policy for ADTEK.

2 Responses

Very interesting read—easy to understand and packed with useful info!

My brother recommended I might like this web site. He was totally right. This post actually made my day. You cann’t imagine simply how much time I had spent for this information! Thanks!